ANCHORGROUT

HIGH STRENGTH, THIXOTROPIC, POLYESTER GROUT

ANCHORGROUT is two components, thixotropic, polyester resin-based anchor grout. When mixed two components it gives high strength, fast setting and fast curing grout of thixotropic consistency. Designed for the anchoring of steel bars and bolts into concrete, machinery and brickwork where speed of installation and early load bearing capacity is required. The cured ANCHORGROUT is resistant to water, oils, petrol greases and mild acids and alkali solutions. ANCHORGROUT permits the production of anchors capable of high loadings.

SALIENT FEATURES

• Rapid strength gain

• Vibration resistant

• Corrosion resistant

• High early strength

• Extremely durable

• Weather resistant

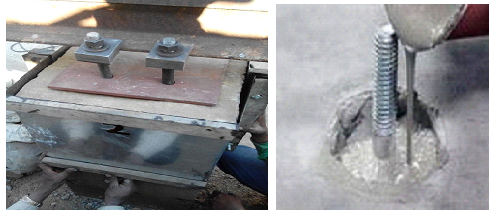

APPLICATION PROCEDURE

Preparation: Hole should be formed using rotary percussive drilling techniques. Diamond drilled holes should be scrabbled. Pre-cast holes should have roughened sides. All dust and drilling debris should be removed. Bars and bolts should be degreased and all rust should be removed.

Mixing: ANCHORGROUT is supplied in pre-weighted two packs. The content of plastic bag should be emptied in metal container, mixed thoroughly to form a smooth paste. Once mixed two components use it in one operation.

Installation: The grout should be injected to the bottom of the hole to avoid entrapment of air. Due to its thixotropic nature, loss of ANCHORGROUT from the hole will be insignificant.

ANCHORGROUT can be used for a permanent installation of reinforcement doweling and starter bars, foundation bolts, base plates, hand rails, safety fences, wall tiles, railway tracks, tie back anchors and grout for tower cranes.

Due to its thixotropic nature it can be used in vertical, horizontal and overhead situations. It can be used in damp conditions. Ideal product for hole grouting having diameter max 25mm & min. 4mm.

PACKING

ANCHORGROUT is supplied in1 Kg

Leave a Reply